The certainty of a recognized delicacy

The quality of the Marcozzi di Campofilone Maccheroncini is officially recognized. 1998: the Marche region recognizes the maccheroncini as a “typical and traditional product of Campofilone”. 2013: the Maccheroncini of Campofilone are granted with the European PGI (Protected Geographical Indication) recognition certificate. This European origin designation imposes the strict compliance to procedural guidelines, strongly bound to the territory of Campofilone. Another recognition obtained by Marcozzi di Campofilone is the European Organic Certification, that guarantees that the product is obtained with production techniques that respect the environment and human health. A product made only with 100% Italian durum wheat semolina and eggs obtained from non-intensive farm where the hens are fed with cereals.

The certainty of a recognized delicacy

The quality of the Marcozzi di Campofilone Maccheroncini is officially recognized. 1998: the Marche region recognizes the maccheroncini as a “typical and traditional product of Campofilone”. 2013: the Maccheroncini of Campofilone are granted with the European PGI (Protected Geographical Indication) recognition certificate. This European origin designation imposes the strict compliance to procedural guidelines, strongly bound to the territory of Campofilone. Another recognition obtained by Marcozzi di Campofilone is the European Organic Certification, that guarantees that the product is obtained with production techniques that respect the environment and human health. A product made only with 100% Italian durum wheat semolina and eggs obtained from non-intensive farm where the hens are fed with cereals.

1. Fresh eggs and durum wheat semolina

Free-range fresh eggs from non-intensive farms from hens fed with no-GMO cereals.

100% Italian grown & milled Durum wheat semolina.

1. Fresh eggs and durum wheat semolina

Free-range fresh eggs from non-intensive farms from hens fed with no-GMO cereals. 100% Italian grown & milled Durum wheat semolina.

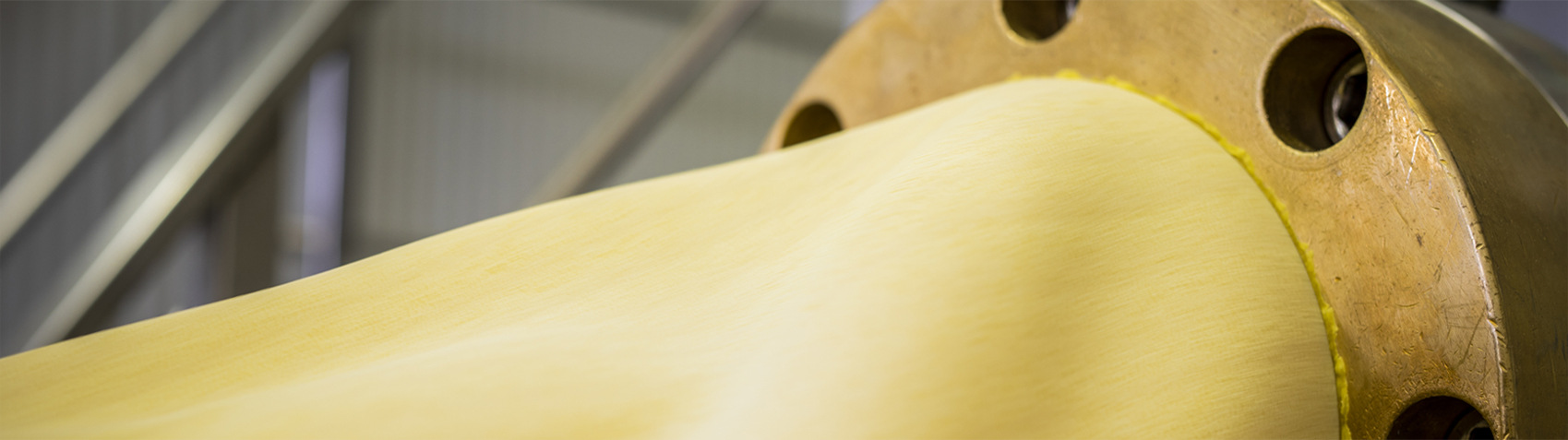

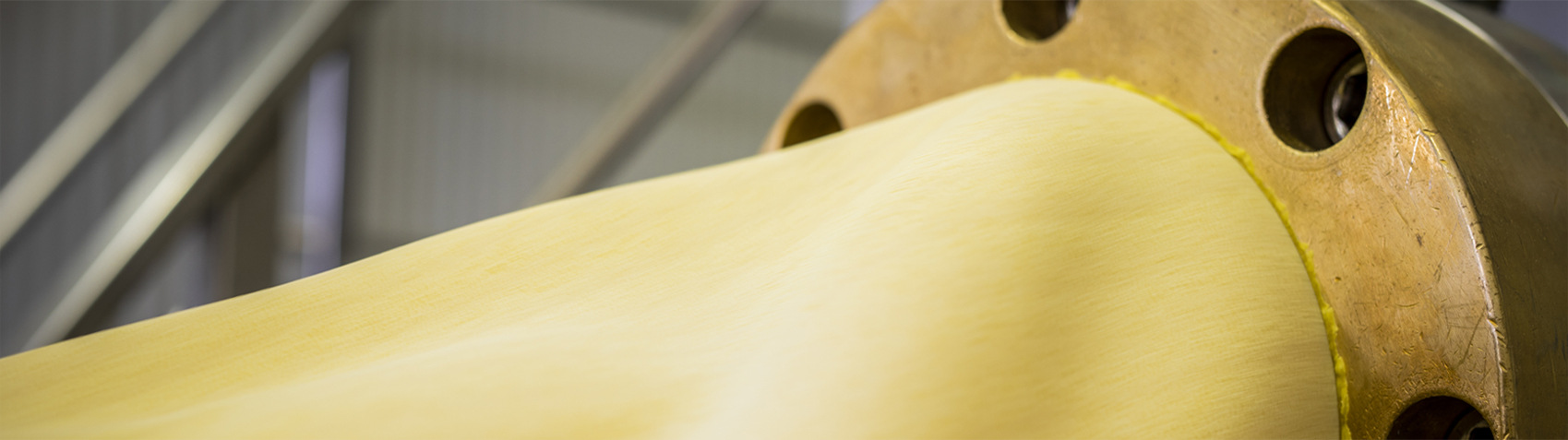

2. Soft dough

The durum wheat semolina is slowly kneaded with the eggs (35% of the total) for at least 30-40 minutes, until the dough is soft and elastic.

2. Soft dough

The durum wheat semolina is slowly kneaded with the eggs (35% of the total) for at least 30-40 minutes, until the dough is soft and elastic.

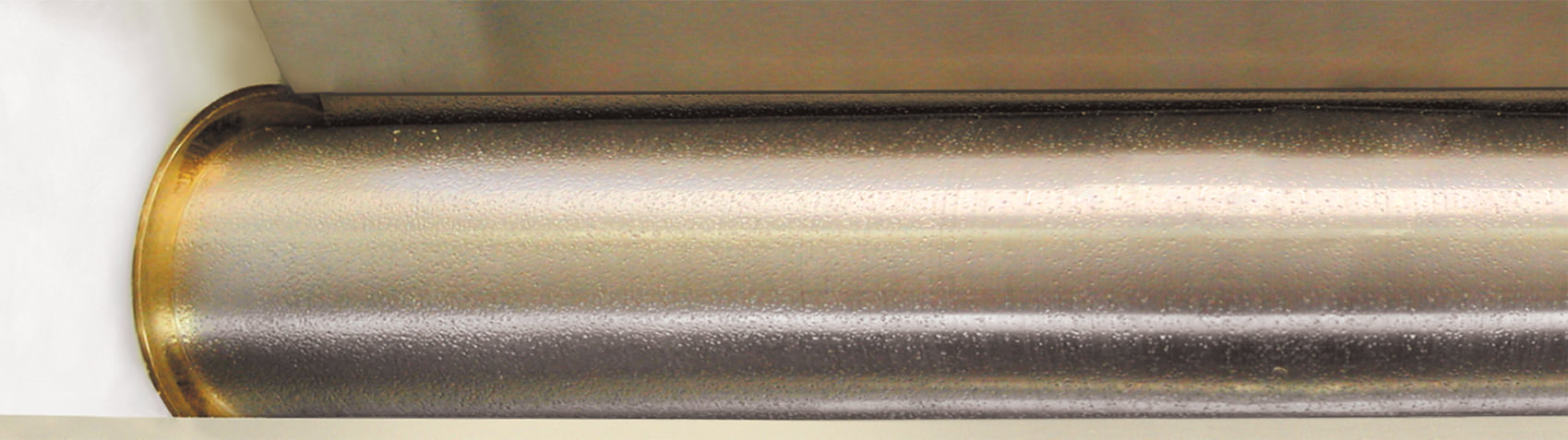

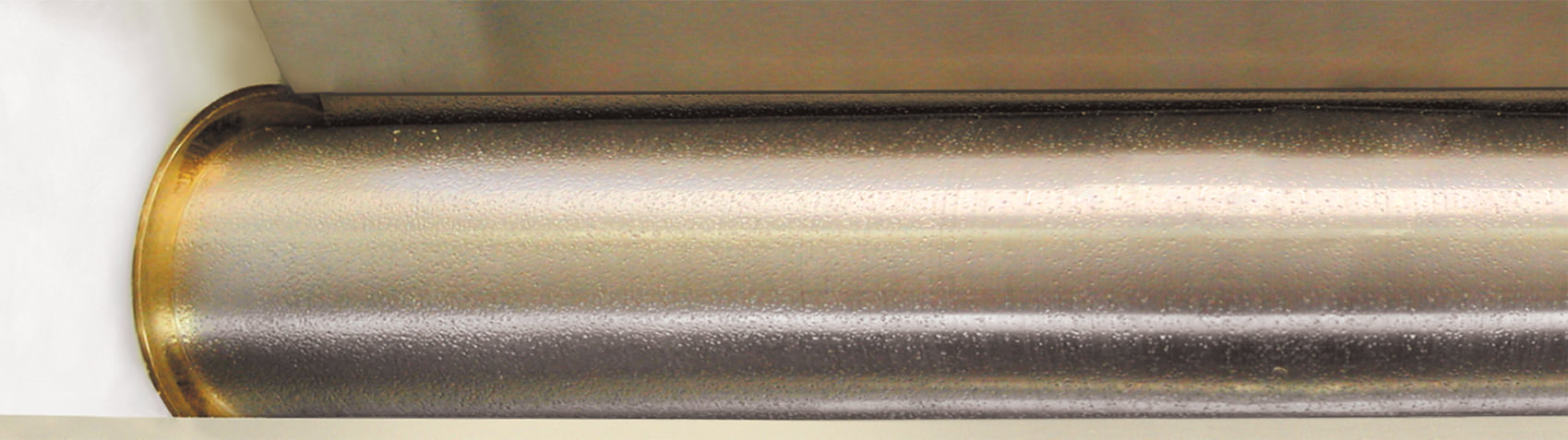

3. Bronze die extrusion

Thanks to the drawing process, the dough takes on a rough and porous appearance, ideal for perfectly blending with any sauce and condiment.

3. Bronze die extrusion

Thanks to the drawing process, the dough takes on a rough and porous appearance, ideal for perfectly blending with any sauce and condiment.

4. Thin and delicate sheet

The pasta dough is rolled into thin sheets that, in the case of the Maccheroncini, are less than 0.7mm thick.

A thinness only few can be proud of, that allows a faster cooking time, a delicate taste, and a pasta easier to digest.

4. Thin and delicate sheet

The pasta dough is rolled into thin sheets that, in the case of the Maccheroncini, are less than 0.7mm thick.

A thinness only few can be proud of, that allows a faster cooking time, a delicate taste, and a pasta easier to digest.

5. The characteristic paper sheets

It’s a typical operation of the Campofilone pasta makers, still entrusted to our most skilled personnel.

It consists in manually laying the pasta strands on paper sheets with the blade of a knife. The sides of the paper are then folded in order to protect the product.

![]()

5. The characteristic paper sheets

![]()

It’s a typical operation of the Campofilone pasta makers, still entrusted to our most skilled personnel.

It consists in manually laying the pasta strands on paper sheets with the blade of a knife. The sides of the paper are then folded in order to protect the product.

6. Slow and gradual drying process

The paper sheets with the fresh pasta are laid on specific frames and then slowly dried (24-34 hours) at low temperatures (28°-55°C).

The drying process is personalized for every shape depending on the humidity and ventilation. Regarding the eco-friendliness of our production, our dryer are powered with photovoltaic energy.

![]()

6. Slow and gradual drying process

![]()

The paper sheets with the fresh pasta are laid on specific frames and then slowly dried (20-36 hours) at low temperatures (28°-54°C). The drying process is personalized for every shape depending on the humidity and ventilation. Regarding the eco-friendliness of our production, our dryer are powered with photovoltaic energy.

7. Strict controls

Weight control with digital scale. Visual control of every produced and dried sheet. Humidity control with thermobalance.

Cooking test and tasting of samples of every batch. Control of the potential presence of metallic particles in the packed product with metal detector. Chemical and microbiological analysis of samples.

7. Strict controls

Weight control with digital scale. Visual control of every produced and dried sheet. Humidity control with thermobalance. Cooking test and tasting of samples of every batch. Control of the potential presence of metallic particles in the packed product with metal detector. Chemical and microbiological analysis of samples.

8. Packaging

Two paper sheets with the dried pasta are manually placed in the case.

The lot number and the expiration date are printed on the case in order to guarantee the traceability on the product.

8. Packaging

Two paper sheets with the dried pasta are manually placed in the case. The lot number and the expiration date are printed on the case in order to guarantee the traceability on the product.